PCD (polycrystalline diamond) cutting tools

PCD tools

Cutting of non-ferrous and non-metal materials with excellent durability and cost effectiveness

Polycrystalline diamond (PCD) tools are most often used to cut non-ferrous and non-metallic materials. They make it possible to improve the quality of parts and significantly reduce costs across the entire production cycle.

・ PCD tools enable fast cutting and feeding speeds.

・ Prolonging the lifespan of tools increases the operating time of machines, thereby significantly improving production capacity with existing equipment.

Cutting of non-ferrous and non-metal materials

with excellent durability and cost effectiveness

Polycrystalline diamond (PCD) tools are most often used to cut non-ferrous and non-metallic materials. They make it possible to improve the quality of parts and significantly reduce costs across the entire production cycle.

・ PCD tools enable fast cutting and feeding speeds.

・ Prolonging the lifespan of tools increases the operating time of machines, thereby significantly improving production capacity with existing equipment.

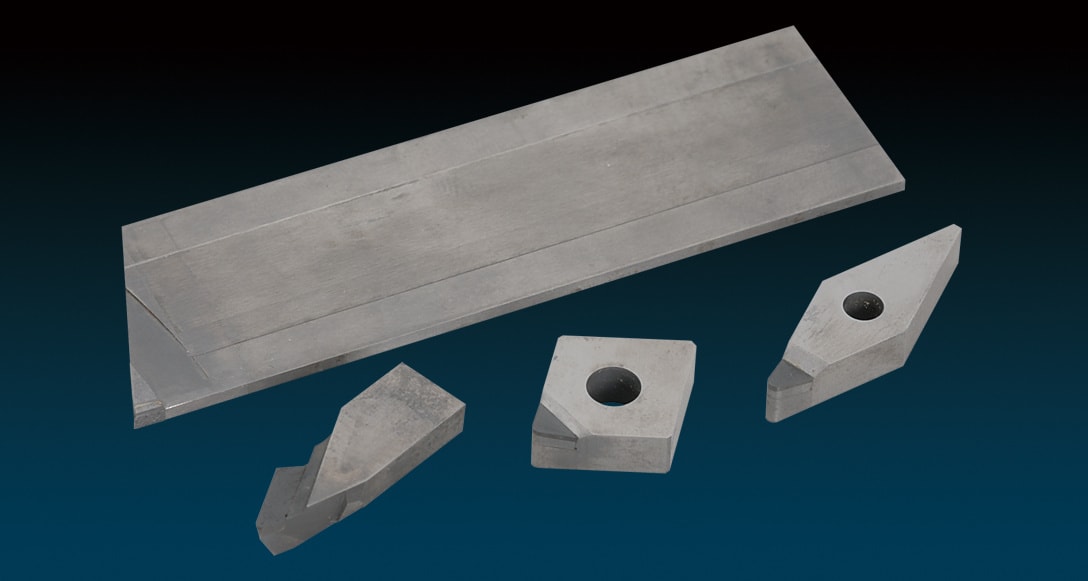

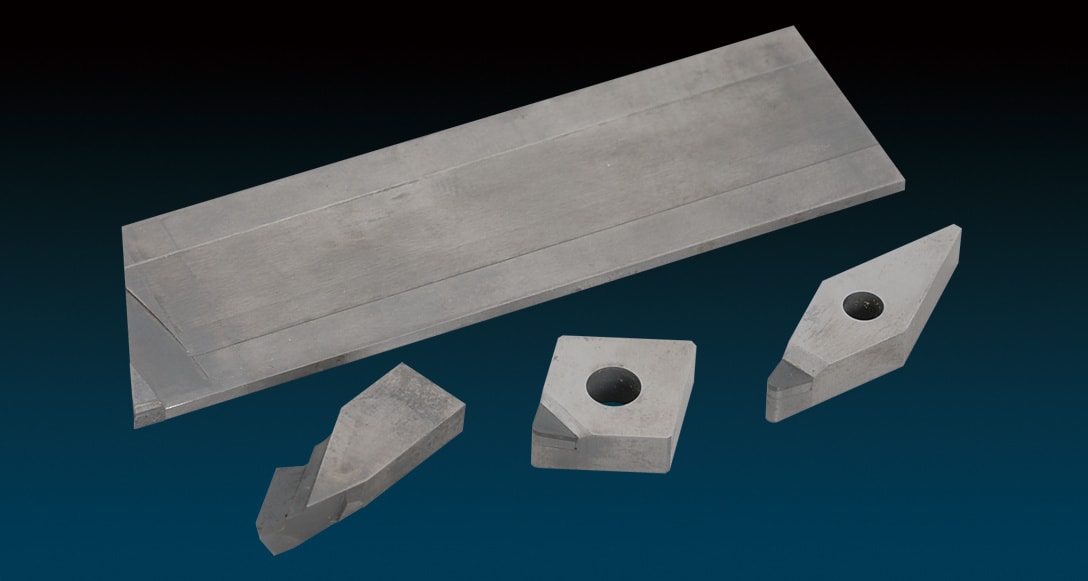

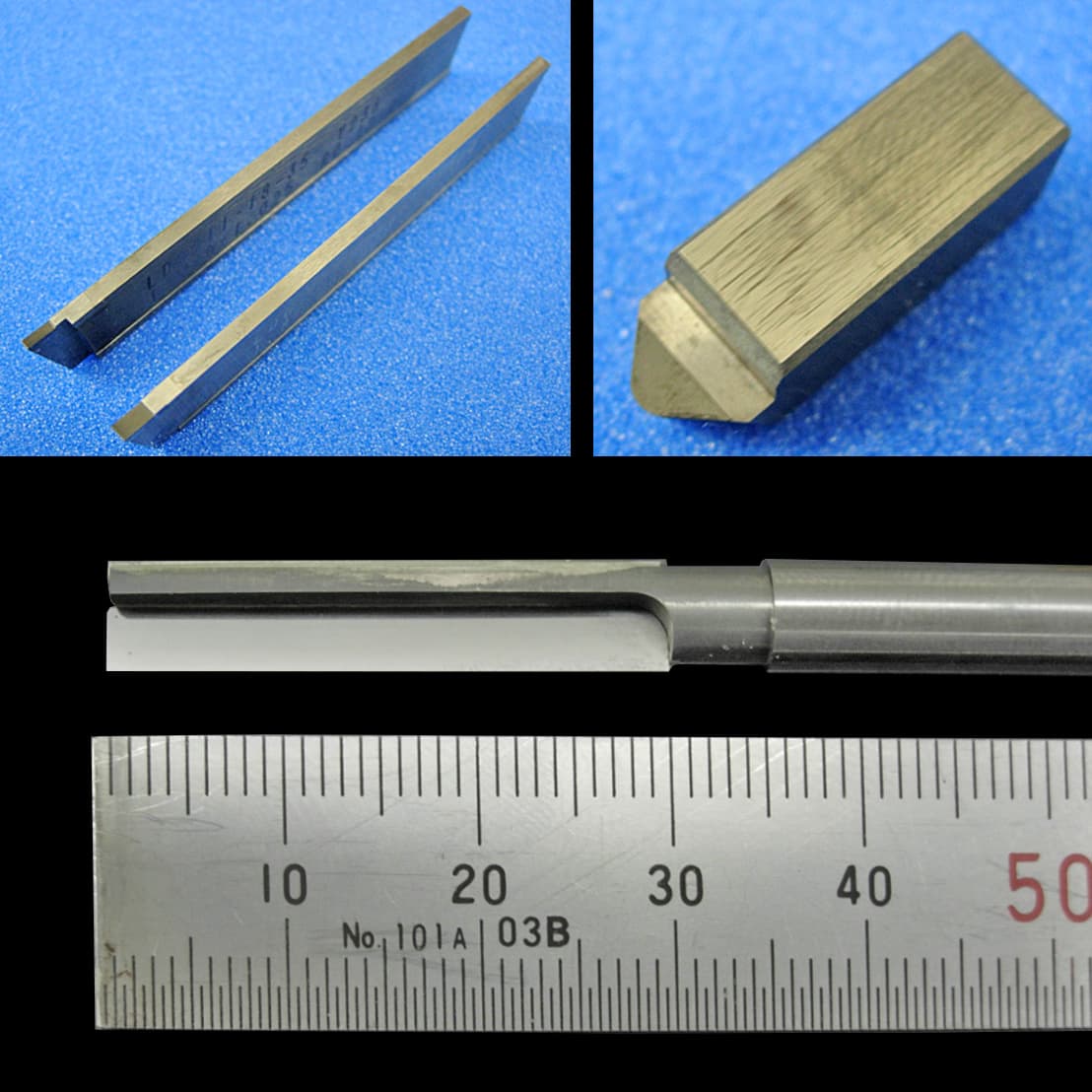

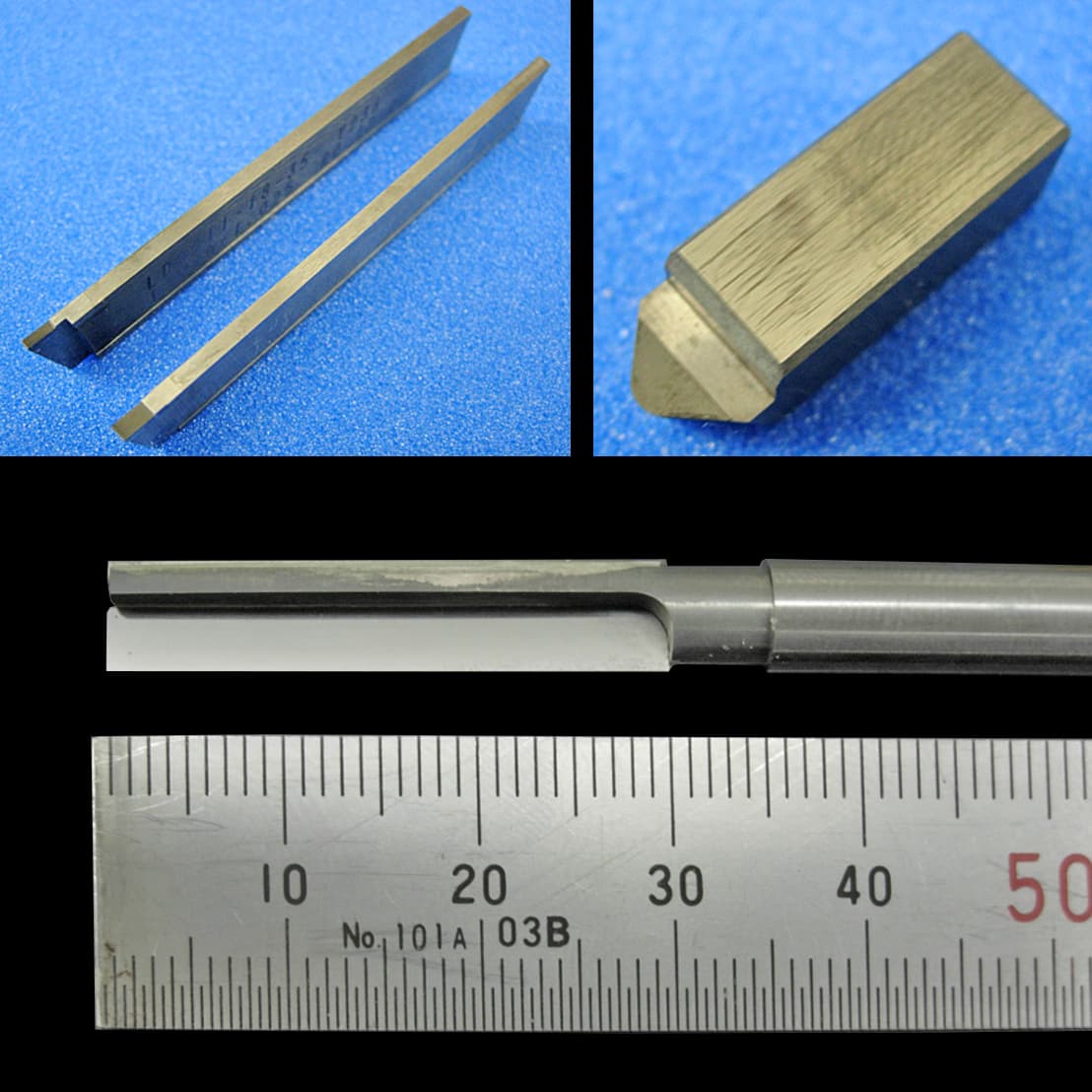

PCD bites / end mills / indexable inserts

PCD bites / end mills / indexable inserts

As performance in automotive component machining improves, better aluminum alloys and improved tool performance are also required. PCD cutting tools provide consistent precision and a lifespan ten times longer than that of carbide tools.

Applications

Aluminum, copper, graphite, resin, ceramics

and other non-ferrous metals

As performance in automotive component machining improves, better aluminum alloys and improved tool performance are also required. PCD cutting tools provide consistent precision and a lifespan ten times longer than that of carbide tools.

Applications

Aluminum, copper, graphite, resin,

ceramics and other non-ferrous metals

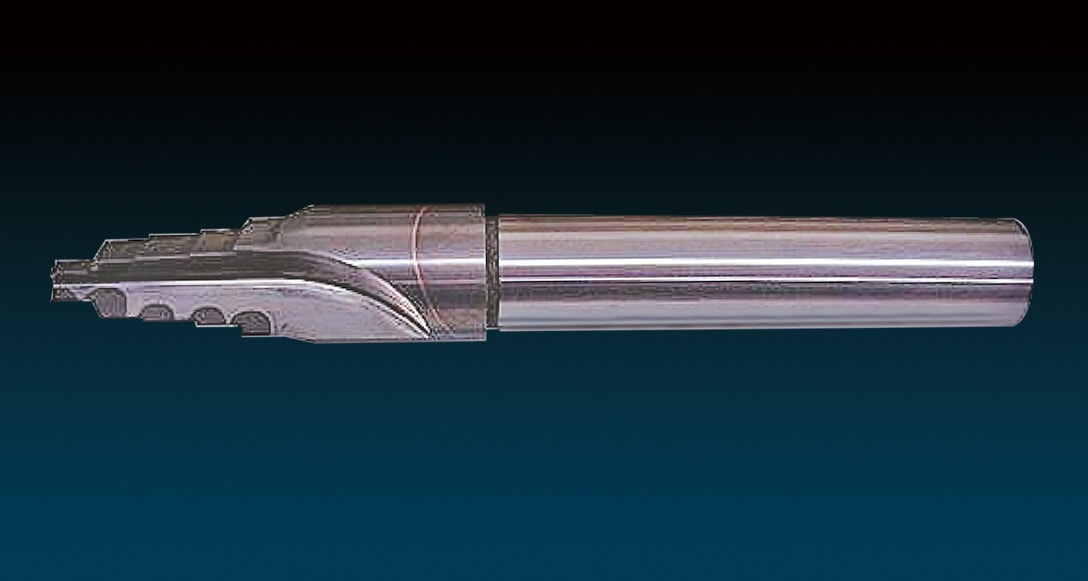

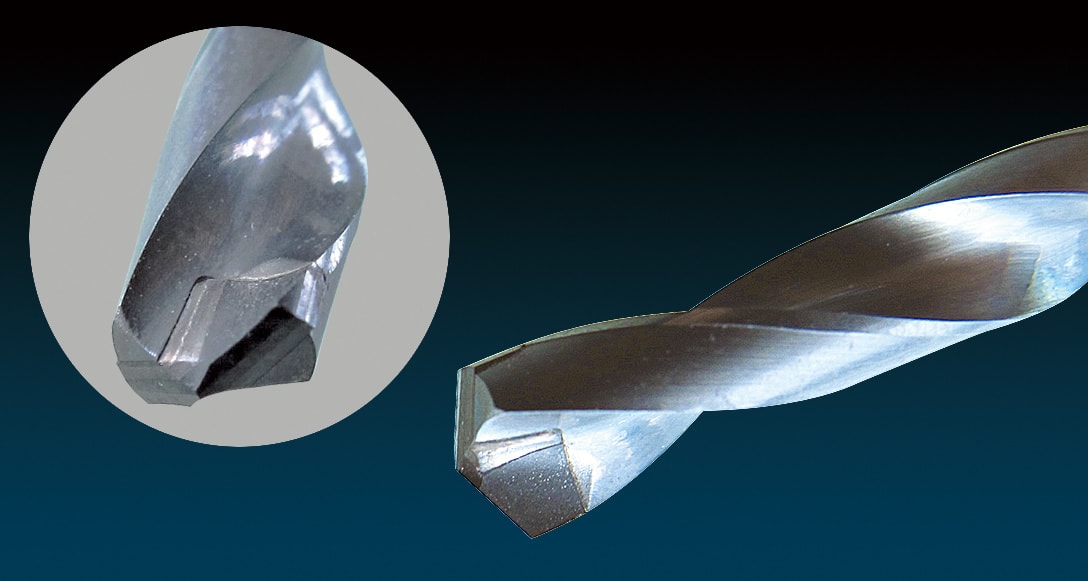

Stepped PCD reamers / drills

Stepped PCD reamers / drills

The stepped shape enables machining with a single tool.

The use of a PCD tip provides improved durability compared to carbide tools.

The screw configuration reduces cutting resistance.

The screw configuration provides a lifespan 20 times that of a standard drill.

* Helix angle: 10° to 30°

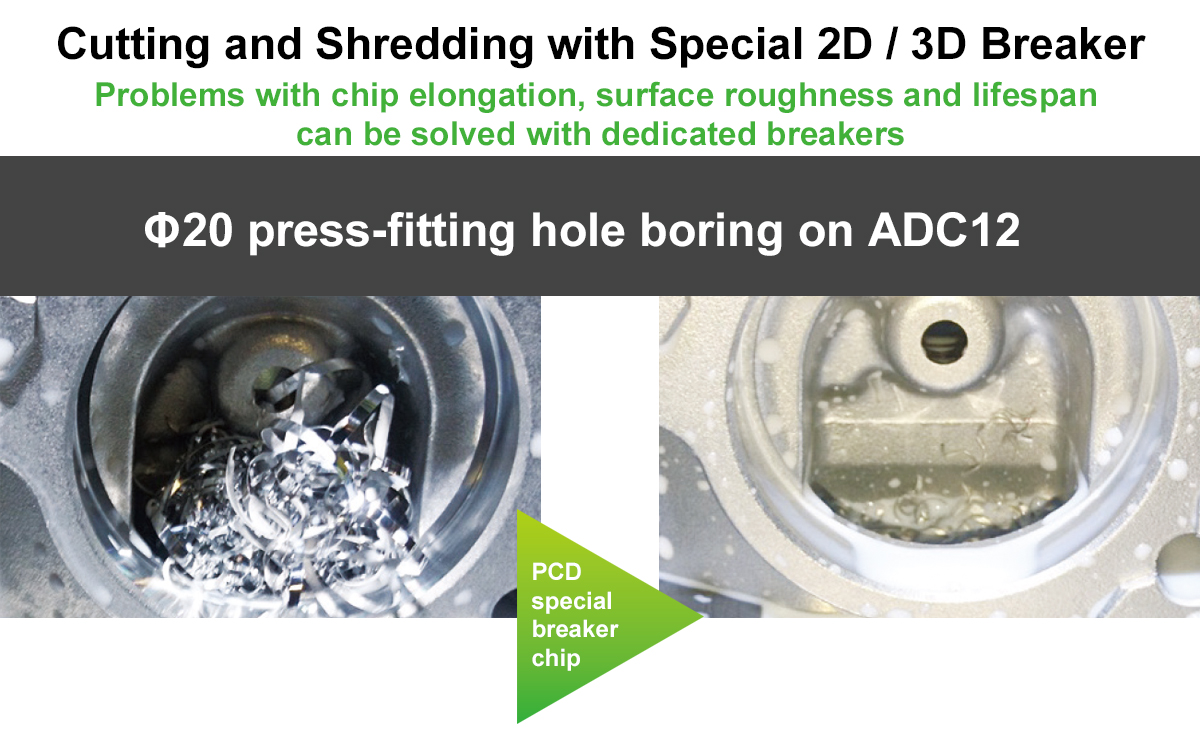

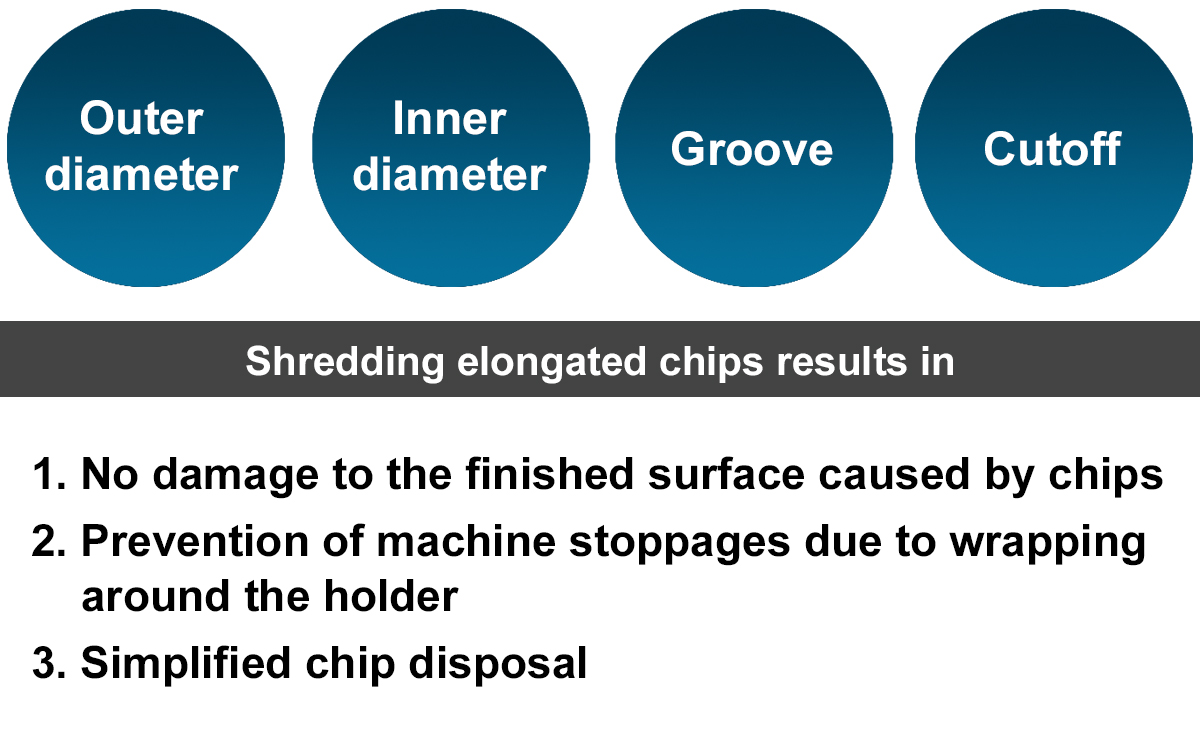

PCD special breaker chip

PCD special breaker chip

PCD bites / CBN end mills

As performance in automotive component machining improves, better aluminum alloys and improved tool performance are also required.

These tools provide consistent precision and a lifespan ten times longer than that of carbide tools.

Applications

Aluminum, copper, graphite, plastics,

ceramics and other non-ferrous metals

PCD bites / CBN end mills

As performance in automotive component machining improves, better aluminum alloys and improved tool performance are also required.

These tools provide consistent precision and a lifespan ten times longer than that of carbide tools.

Applications

Aluminum, copper, graphite, plastics,

ceramics and other non-ferrous metals

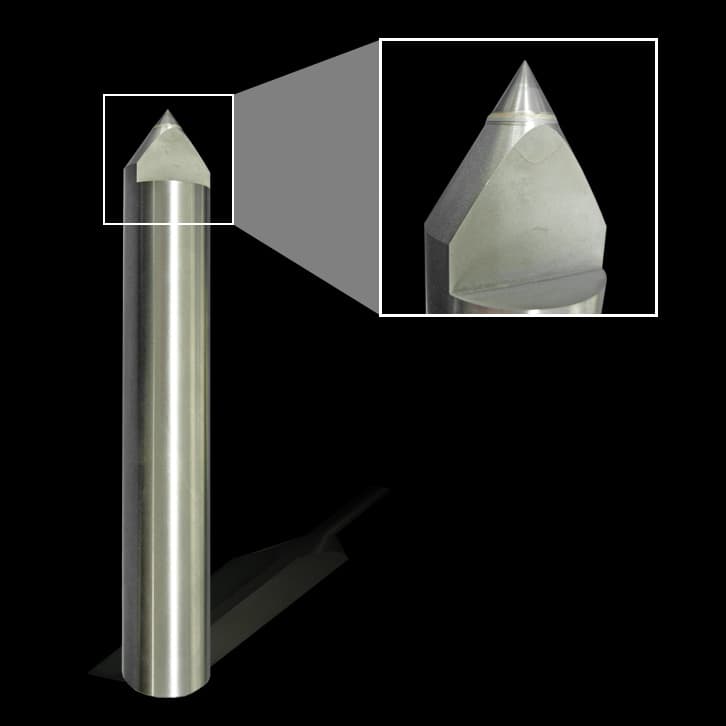

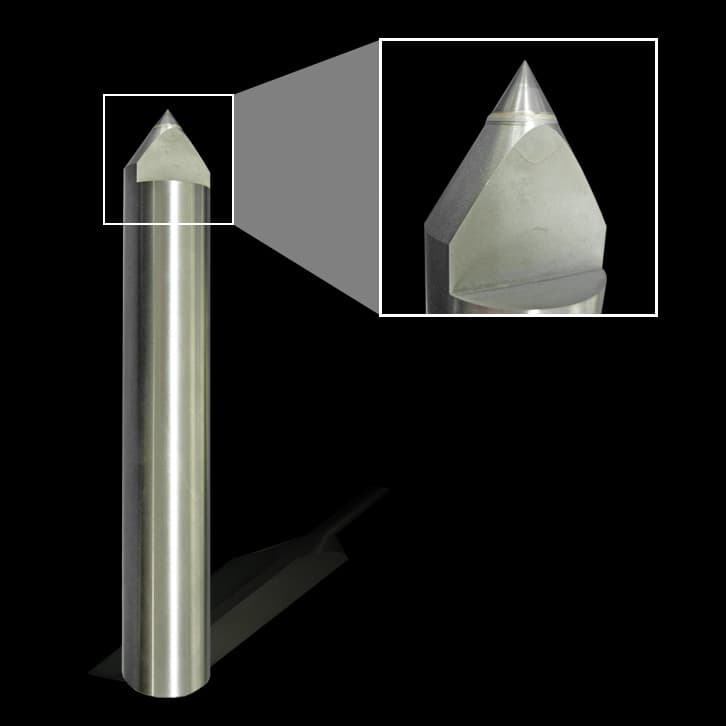

PCD lathe center

PCD has excellent wear resistance and a small coefficient of friction compared to carbide. Machining accuracy can be maintained for a long period of time by using PCD tips.

PCD lathe center

PCD has excellent wear resistance and a small coefficient of friction compared to carbide. Machining accuracy can be maintained for a long period of time by using PCD tips.

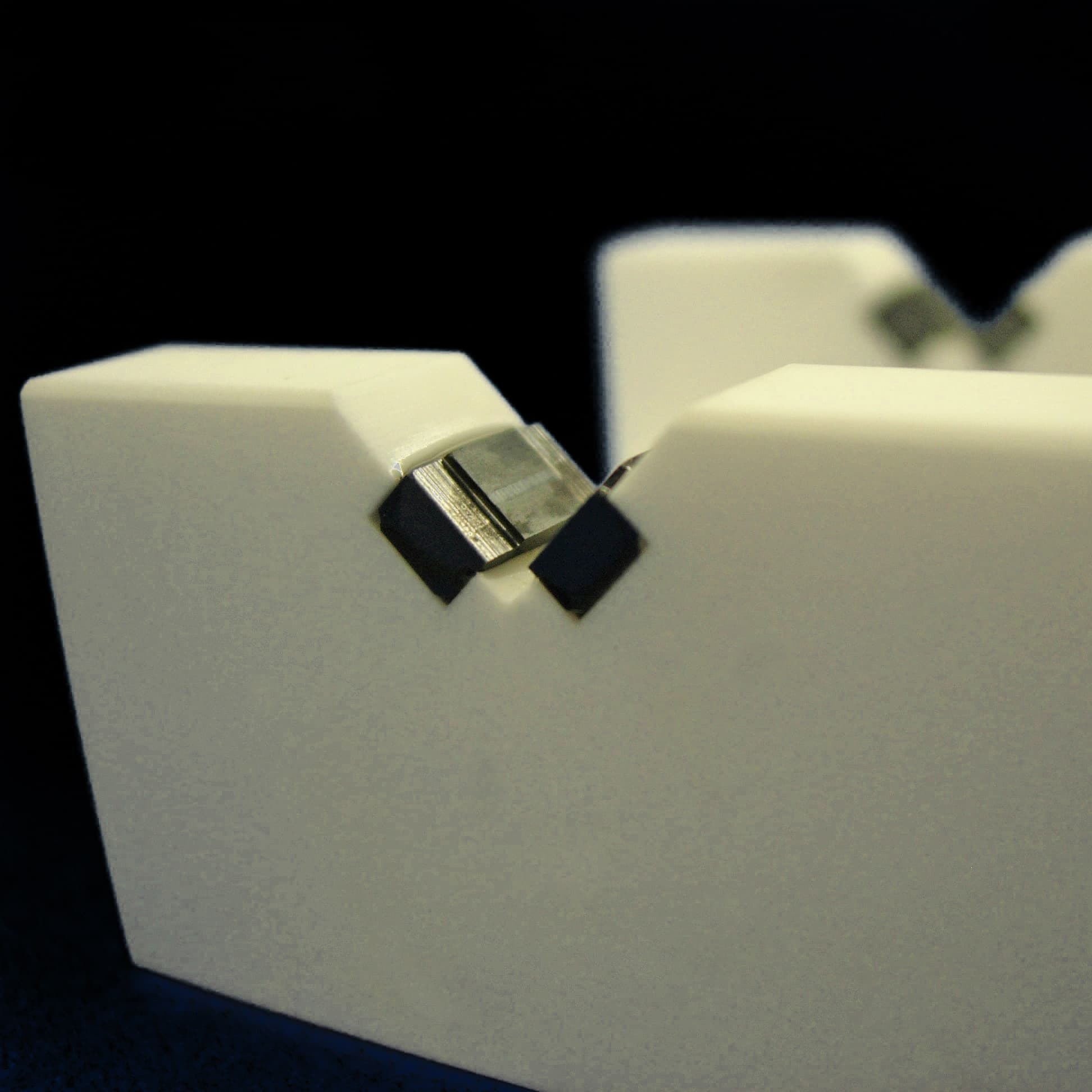

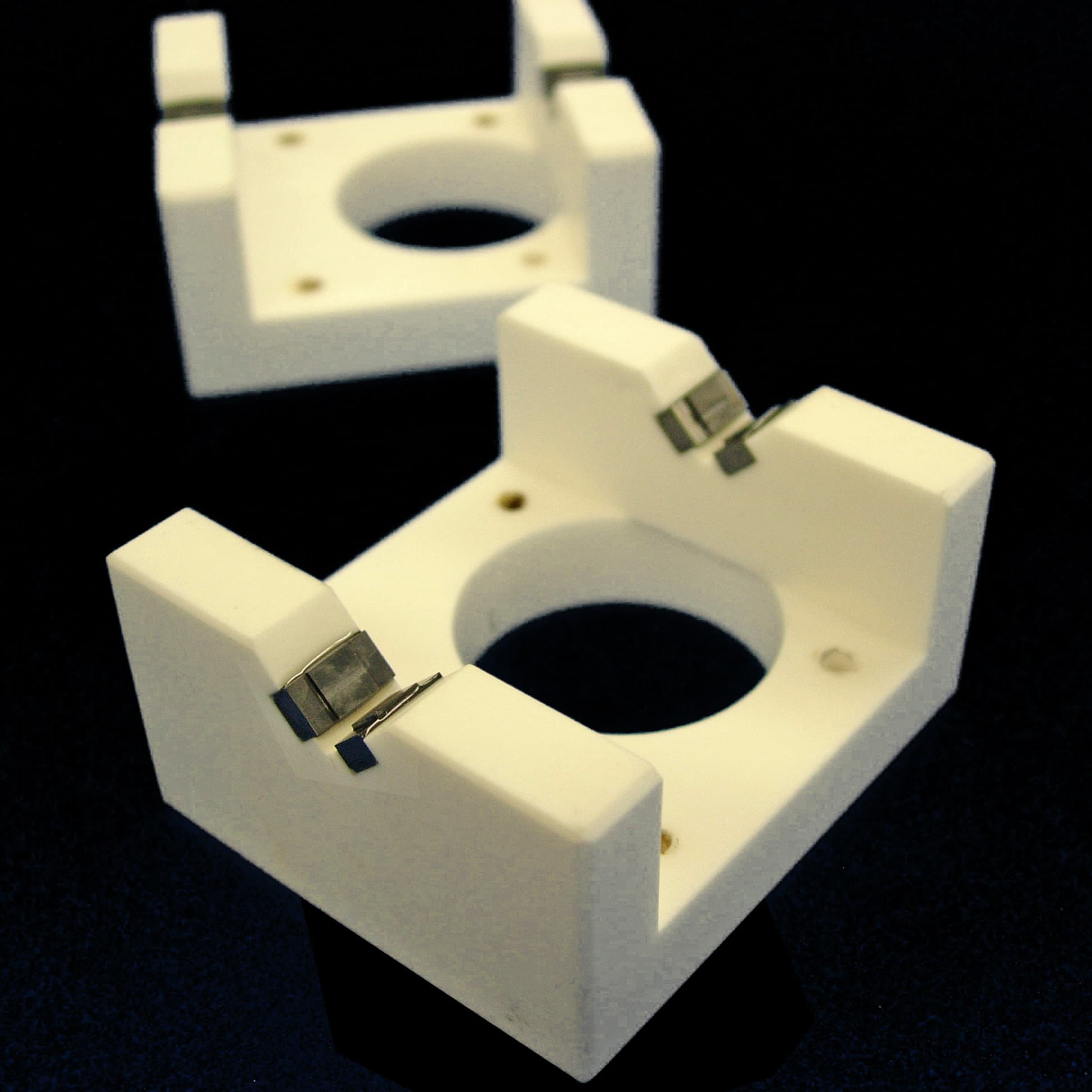

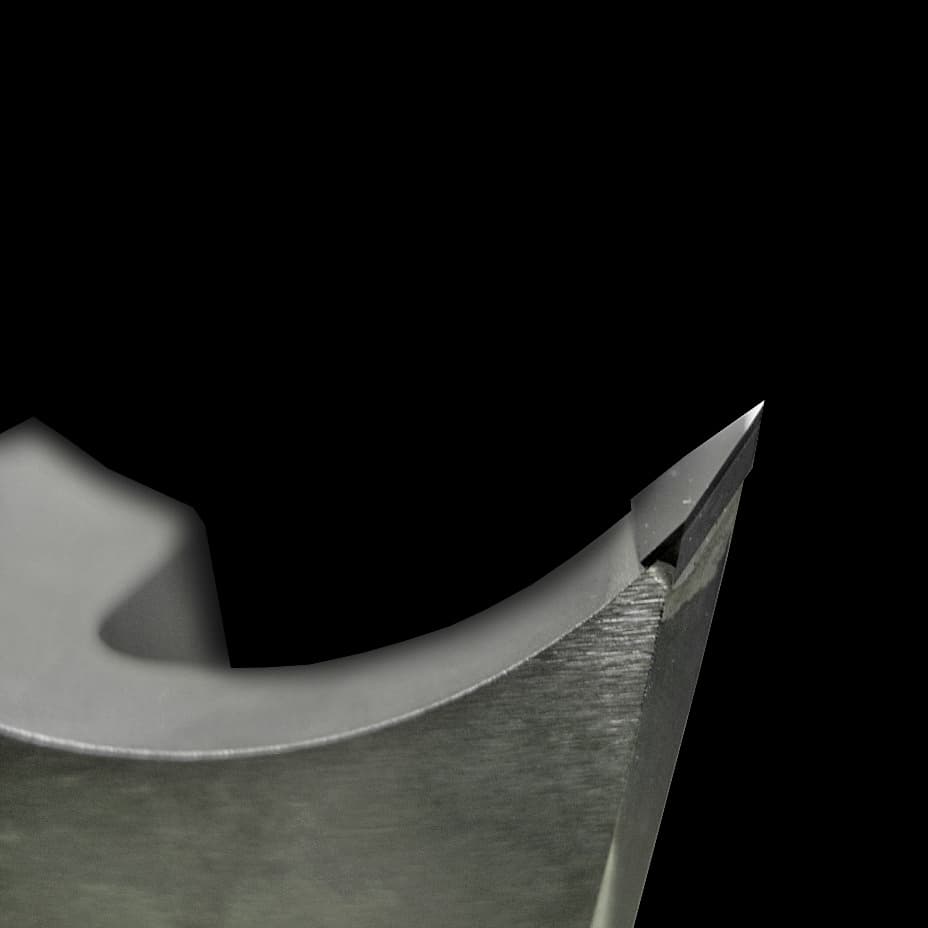

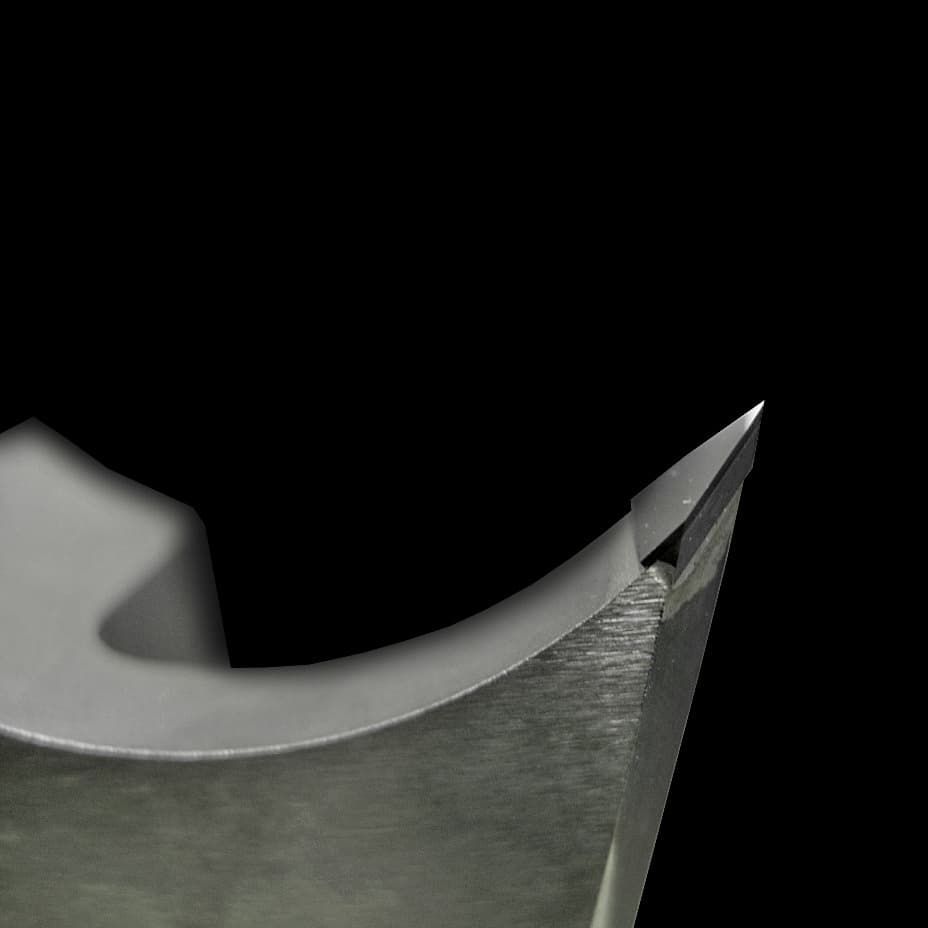

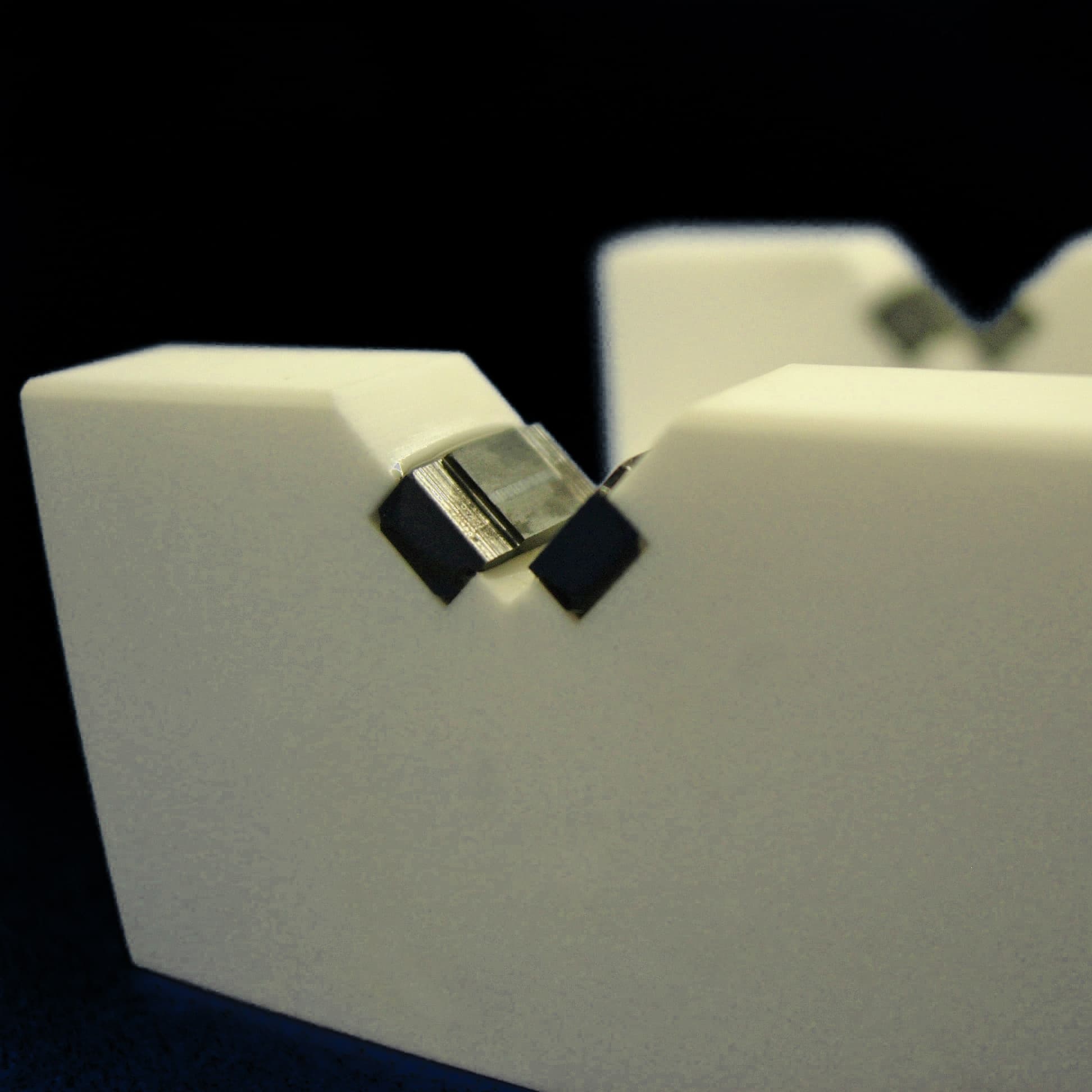

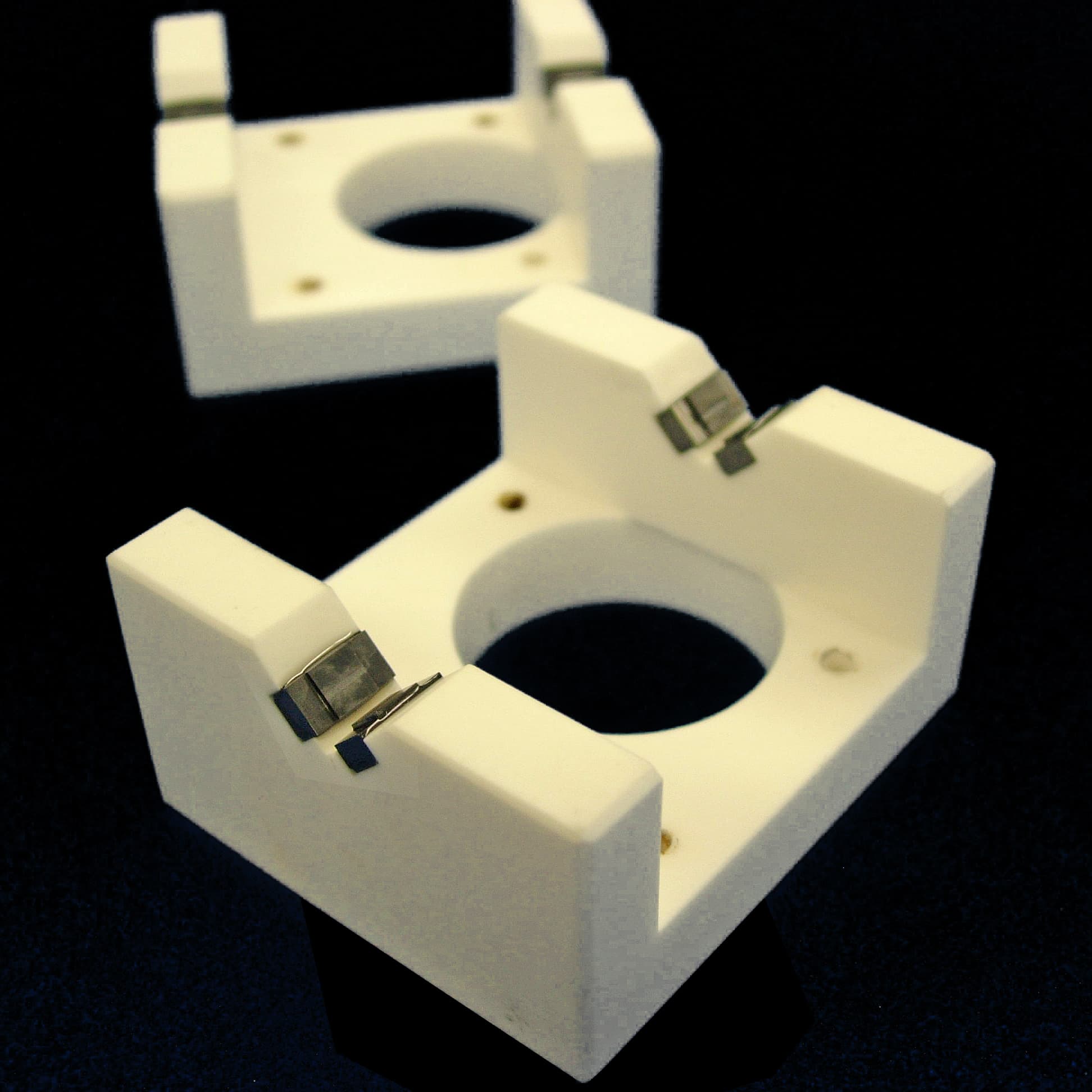

PCDV block

Jigs that hold cylindrical products and feature PCD on parts that come into contact with the product. Prolonging the lifespan results in improved productivity.

PCDV block

Jigs that hold cylindrical products and feature PCD on parts that come into contact with the product. Prolonging the lifespan results in improved productivity.